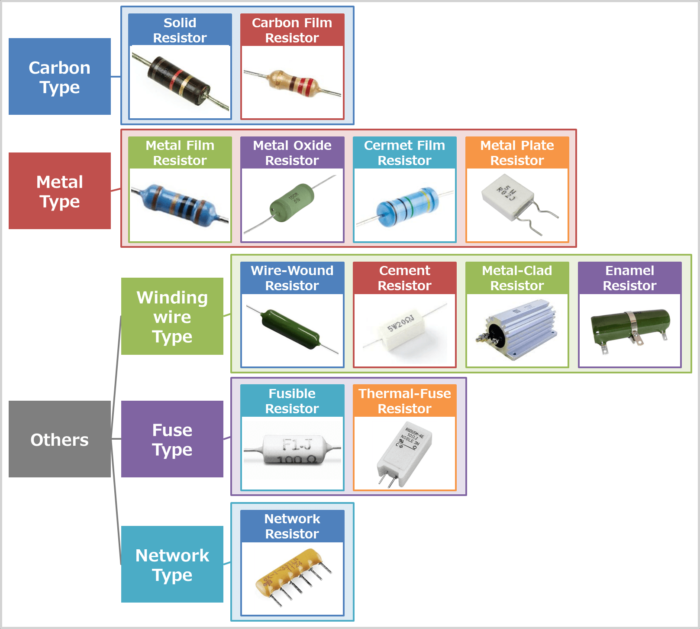

There are many different types of resistors.

Regarding the Resistor, this article will explain the information below.

- Types of Resistors

- Characteristics of each resistance (advantages and disadvantages, etc.)

Types of Resistors

There are many types of resistors, which can be classified mainly according to their characteristics and materials as shown in the figure above.

The resistors that are very inexpensive and most widely used are carbon film resistors. In addition, metal plate resistors with low resistance, high power (several watts), and small inductance are used to detect the current flowing in a circuit.

The following is a detailed explanation of each type of resistor.

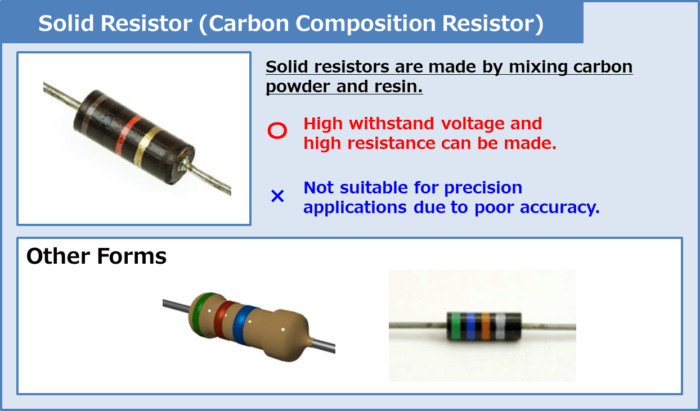

Solid Resistor (Carbon Composition Resistor)

Solid resistors are made by mixing carbon powder and resin.

Solid resistors are mainly used in circuits subject to high stress, such as power supply circuits because they can be made with high withstand voltage and high resistance.

However, they are not suitable for precision applications due to their poor accuracy. Solid resistors also have drawbacks in terms of cost and accuracy and are gradually being replaced by carbon film resistors.

Solid resistors are also called carbon composition resistors.

Advantages

- High withstand voltage and high resistance can be made.

- Small parasitic inductance component.

- Less susceptible to wire breakage.

- Strong and durable under transient conditions.

- Can manufacture ultra-compact resistors such as 1/16W type.

- A wide range of resistance values can be covered.

Disadvantages

- Not suitable for precision applications due to poor accuracy.

- Resistance changes significantly over time.

- The Temperature coefficient is very large, and the resistance value may increase significantly at extremely high temperatures.

- Poor availability, as many domestic manufacturers discontinue production due to age-related deterioration of resistance value and poor productivity.

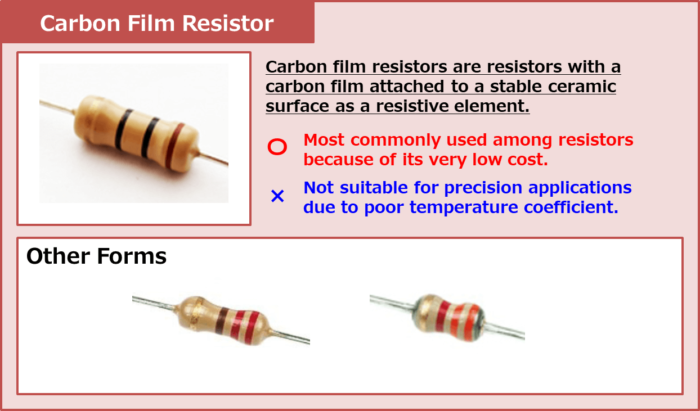

Carbon Film Resistor

Carbon film resistors are resistors with a carbon film attached to a stable ceramic surface as a resistive element.

Carbon film resistors are most commonly used in resistors for low-power applications and are usually referred to as small resistors.

Resistance accuracy is generally ±5% (J) and ±10% (K), and the temperature coefficient is negative (resistance decreases with increasing temperature).

Advantages

- Most commonly used among resistors because of their very low cost.

- A wide range of resistance values can be covered.

Disadvantages

- Not suitable for precision applications due to poor temperature coefficient.

- Current noise and frequency characteristics are not good.

Supplement

- Carbon film resistors have grooves on the inside when the paint is removed. By adjusting this groove, the resistance value is adjusted.

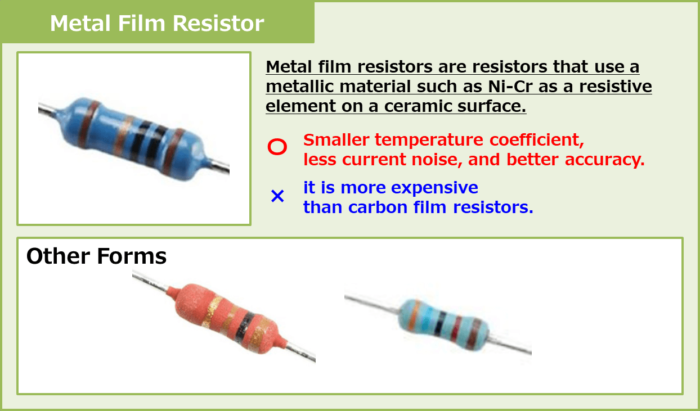

Metal Film Resistor

Metal film resistors are resistors that use a metallic material such as Ni-Cr (nickel-chromium) as a resistive element on a ceramic surface.

The appearance of metal film resistors is similar to that of carbon film resistors.

Advantages

- Compared to carbon film resistors, it has a smaller temperature coefficient, less current noise, and better accuracy.

- A wide range of resistance accuracy options is available, including ±5% (J), ±2% (G), ±1% (F), ±0.5% (D), ±0.25% (C), ±0.1% (B), and ±0.05% (A).

Disadvantages

- Since metal is used as the resistive element, it is more expensive than carbon film resistors (about 2 to 3 times more expensive).

Supplement

- There are two types of metal film resistors: "thick film type metal film resistors (made by heating and firing metallic paste)" and "thin film type metal film resistors (made by depositing and coating metal)". Among these two types, the thick-film type is the general-purpose metal film resistor. The thin-film type has higher accuracy (±0.05% in some cases) and lower temperature coefficient than the thick-film type but is more expensive than the thick-film type.

- Because of its high accuracy, it is mainly used in communication and measurement equipment and computers.

- The temperature characteristics of metals in general are positive. Therefore, the temperature coefficient of metal film resistance is reduced by changing the ratio of alloys. Depending on the alloy ratio, it can be either a positive or negative characteristic.

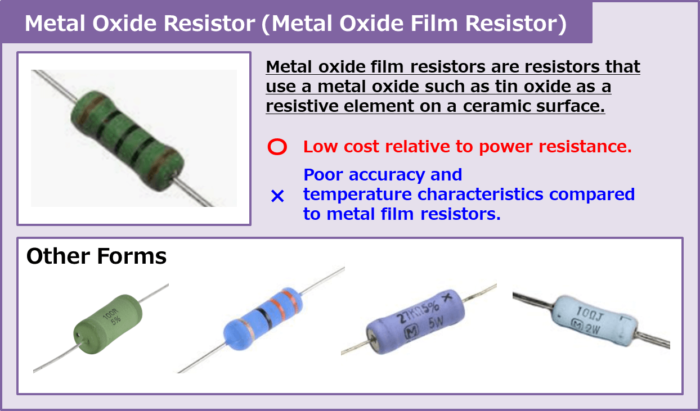

Metal Oxide Resistor (Metal Oxide Film Resistor)

Metal oxide film resistors are resistors that use a metal oxide such as tin oxide as a resistive element on a ceramic surface.

Since the film of metal oxide film resistors does not burn up due to heat, they are often used for medium power applications ranging from 1W to 5W.

Advantages

- Low cost relative to power resistance.

Disadvantages

- Poor accuracy and temperature characteristics compared to metal film resistors.

Supplement

- The resistive element material, metal oxide, is an inorganic material, which generates heat without combustion. Therefore, care must be taken in mounting. It is necessary to control the temperature of the components (capacitors, etc.), wiring, and printed circuit board around the resistor.

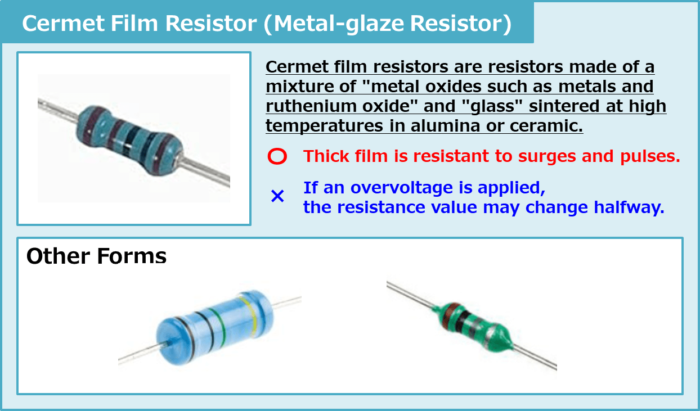

Cermet Film Resistor (Metal-Glaze Resistor)

Cermet film resistors are resistors made of a mixture of "metal oxides such as metals and ruthenium oxide" and "glass" sintered at high temperatures in alumina or ceramic.

Cermet film resistors are also called metal-glaze resistors.

Advantages

- The Thick film is resistant to surges and pulses.

- Excellent corrosion resistance.

- High reliability with little change in resistance value over time, even in high-resistance regions.

- Excellent safety and environmental resistance.

Disadvantages

- Since insulating particles are used, when overvoltage is applied, the load may be concentrated on some insulating particles, causing local dielectric breakdown and resulting in changes in resistance.

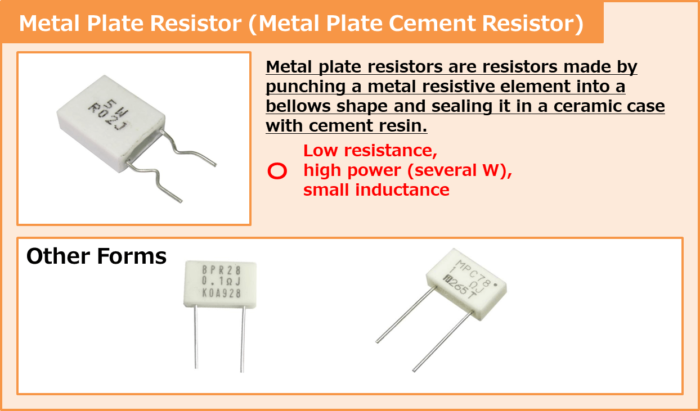

Metal Plate Resistor (Metal Plate Cement Resistor)

Metal plate resistors are resistors made by punching a metal resistive element into a bellows shape, attaching a lead, and sealing it in a ceramic case with cement resin.

Metal plate resistors are characterized by low resistance, high power (several W), and small inductance.

Advantages

- It has low resistance (can be manufactured from 10 mΩ), high power (several W), and small inductance. For this reason, they are used in current detection circuits.

- Because of its low resistance, the wiring resistance of printed circuit boards must be considered.

- Since it is an inorganic material, it does not burn.

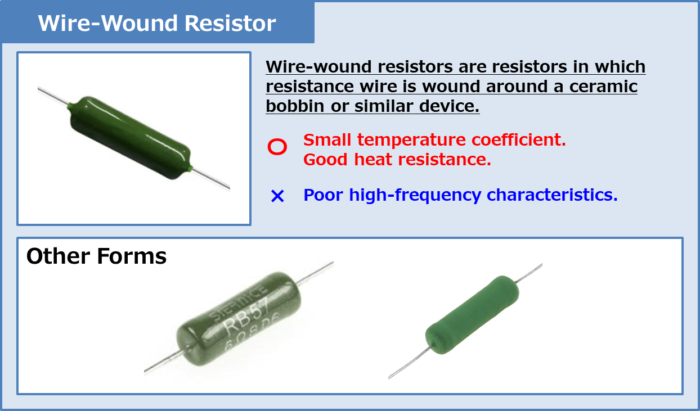

Wire-Wound Resistor

Wire-wound resistors are resistors in which resistance wire (thin metal wire, manganese or nichrome wire, etc.) is wound around a ceramic bobbin or similar device.

Wire-wound resistors are characterized by their ability to provide high power (several W to several 100 W) at low resistance values.

Advantages

- Small temperature coefficient.

- Low current noise.

- Good heat resistance.

Disadvantages

- Poor high-frequency characteristics.

- The structure of winding a resistor wire around a bobbin is the same as that of an inductor and has an inductance component. Therefore, care must be taken in high-frequency circuits.

- High-resistance ones are large and expensive.

Supplement

- The resistance value is adjusted by wire type and number of windings.

- Wire-wound resistors are available in two types: those for power applications and those for precision applications. Most of those generally available on the market are for power applications.

- Because of its heat-resistant construction, the resistor becomes very hot when used at rated power. Therefore, care must be taken in mounting. It is necessary to control the temperature of the components (capacitors, etc.), wiring, and printed circuit board around the resistor.

- Some products have poor high-frequency characteristics due to their structure, which can be counteracted by using a non-inductive winding method. However, even with non-inductive windings, it is safe to avoid using the product at high frequencies.

- Temperature coefficients vary with each product type.

- Wire-wound resistors are often used for high-power applications and must be heat resistant (no smoking or ignition). For this reason, many cases use nonflammable paint for insulation. Those using square cement material for the case are called ceramic cement resistors, while those using metal cases are called metal clad resistors.

Ceramic Cement Resistor

Ceramic cement resistors are resistors with improved heat and pressure resistance by placing wire-wound resistors or metal film resistors in a ceramic case and sealing them with cement.

Ceramic cement resistors are for high-power applications and are used when high-power resistance is required.

Advantages

- Excellent insulating properties.

- Cement has good heat dissipation properties, which improves heat resistance.

Disadvantages

- Because of its wire-wound structure, it has an inductance component. Therefore, care must be taken in high-frequency circuits.

Supplement

- Since it is covered by a nonflammable case, it does not ignite. When used at rated power, the resistor becomes very hot. Therefore, care must be taken when mounting. It is necessary to control the temperature of the components (capacitors, etc.), wiring, and printed circuit board around the resistor.

Metal-Clad Resistor

Metal-clad resistors are wire-wound resistors with a metal exterior. They are a type of wire-wound resistor.

Since metal-clad resistors are designed to carry a large current, some of them have thermal countermeasures such as heat sinks and heat dissipation fins.

Enamel Resistor

Enamel Resistors are resistors with a ceramic core around which resistance wire is wound and enamel is baked to enhance heat resistance. They are a type of wire-wound resistor.

Some enamel resistors have the surface coating shaved off to expose the resistor wire, and the resistance value can be adjusted by attaching a slide fitting. These resistors are called vitreous enamel resistors.

Advantages

- Extremely high heat resistance makes it suitable for handling large amounts of power.

Disadvantages

- Because of its wire-wound structure, it has an inductance component. Therefore, care must be taken in high-frequency circuits.

Fusible Resistor

Fusible resistors are resistors that function as ordinary resistors under normal conditions, and in abnormal conditions such as overload, the resistive element completely melts and interrupts the circuit current.

This is based on the phenomenon that the resistive element melts like a fuse at high temperatures. Structurally, it has the same structure as a metal oxide film resistor, but the exterior coating is flame-retardant to prevent the resistive element from burning.

Fusible resistors have a larger variation in response current and response time than fuses and thermal-fuse resistors.

Thermal-Fuse Resistor

Thermal-Fuse Resistors are mainly used to suppress the inrush current that flows when the power supply is turned on.

When the power supply is turned on, an inrush current protection circuit is connected between the power supply lines to suppress the inrush current flowing in the power supply lines. For this resistor, a wire-wound resistor with a large surge withstands capacity that can withstand the inrush current that flows when the power supply is turned on can be used.

Under normal conditions, turning on the switching device allows current to flow through the switching device. However, if the switching device malfunctions, current will continue to flow through the resistor, causing the resistor to heat up considerably. As a safety measure, a thermal fuse is integrated near the resistor. These components are called Thermal-Fuse Resistors.

Network Resistor

Network resistors are resistors that combine multiple resistors on a single insulating substrate.

It is beginning to be widely used due to its advantages such as reduced number of parts, labor saving, and high density.

The characteristics of the resistors are the same as those of general thick-film resistors. There are various ways to connect multiple resistors, such as parallel, series, voltage divider, and independent.

Supplement

- Network resistors are used when you want to reduce relative resistance variation.

Summary

This article described the following information about "resistors".

- Types of Resistors

- Characteristics of each resistance (advantages and disadvantages, etc.)

Thank you for reading.